When it comes to 3D printing, the sky is the limit. As 3D printing technology continues to advance, applications can be as far reaching as airplane and automobile parts to medical devices and even anatomically correct, biocompatible models. Although 3D printing technology is developing at a rapid pace, the technology itself is not new. It emerged in the 1980s as a means of creating rapid prototypes. In recent years the applications for 3D printed models have evolved with the available hardware, software, and printable materials. Evolving technology, paired with the creative and innovative minds of scientists, engineers, and physicians, has been the launching pad for developments within 3D printing technology specific to healthcare. One way 3D printing technology is poised to create better patient outcomes is in creating an anatomically and patient-specific models to aid in surgery and medical procedures. With the capability to 3D ...

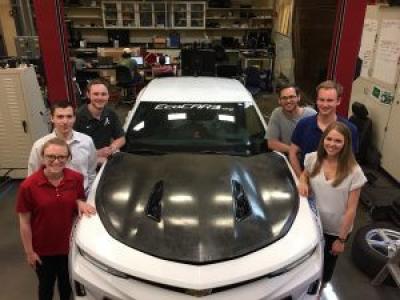

Researchers at The University of Alabama used graphene to fabricate a lighter car hood, as part of an attempt to reduce the weight of a Chevrolet Camaro. The new hood is made of a mixture of graphene and carbon fiber, as opposed to the original hood which is made of aluminum.The hood is half the weight of the original hood, a crucial adjustment as a larger team of students work to turn the Camaro into a plug-in hybrid as part of a national contest called EcoCAR 3.

After months of computer modeling and material tests, the team settled on a carbon fiber hood with less than one percent of graphene. They made resin of the material that they vacuum infused into a mold of the hood, later drilling and finishing the hood to fit onto the Camaro. The new hood weighs 11.1 pounds, less than the 22.1 pounds of the original hood, meeting the goal to cut the weight of the hood in half.

Using a testing apparatus they constructed, the students mimicked a 30-mph head-on collision with weights. The hood buckled under the force without splitting, and, in fact, returned to its original form after crash, demonstrating flexibility.

The engineering students beat the project constraint of keeping the cost of their hood within five times the cost of the original hood despite not having advantages of a large-scale factory. In fact, the student team estimates the new hood costs less than twice that of the original aluminum hood.

Comments

Post a Comment