When it comes to 3D printing, the sky is the limit. As 3D printing technology continues to advance, applications can be as far reaching as airplane and automobile parts to medical devices and even anatomically correct, biocompatible models. Although 3D printing technology is developing at a rapid pace, the technology itself is not new. It emerged in the 1980s as a means of creating rapid prototypes. In recent years the applications for 3D printed models have evolved with the available hardware, software, and printable materials. Evolving technology, paired with the creative and innovative minds of scientists, engineers, and physicians, has been the launching pad for developments within 3D printing technology specific to healthcare. One way 3D printing technology is poised to create better patient outcomes is in creating an anatomically and patient-specific models to aid in surgery and medical procedures. With the capability to 3D ...

A team that includes researchers from the University of Delaware says it has invented a cheap, high-yield process that can be used to make rubber and plastics from renewable sources such as grass, corn, and trees.

The announcement was made online as a letter in the ACS Sustainable Chemistry and Engineering journal, a publication of the American Chemical Society.

“This research could transform the multibillion-dollar plastics and rubber industries,” said report co-author Dionisios Vlachos, a biomolecular engineering professor at Delaware and director of the university’s Catalysis Center for Energy Innovation. The research team included scientists from the University of Minnesota and the University of Massachusetts.

Essentially, the team discovered a catalyst that can be used in the process of making butadiene, a chief chemical building block for rubber and hard plastics. The butadiene can form the base of products used to make tires, toys, and other products. The process is cheaper than traditional methods and produces high yields of butadiene, Vlachos said.

Plastics traditionally are made from a process involving fossil fuels, such as crude oil and natural gas.

Although the new process relies on plants, the end products are not biodegradable, according to Vlachos. But the manufacturing process is better for the environment than traditional ways of making plastic, he said in an email. Carbon dioxide, a greenhouse gas, gets removed and “stored” in the product, such as a tire, he said. The tire can then be recycled.

“This, in a way, is better than biodegradable where the carbon goes back to the air,” Vlachos said.

The chemical reaction involving butadiene can be used to manufacture hoses, seals, rubber gloves, and even hard ABS-type plastics — the stuff of auto parts, sporting goods, video game consoles, and interlocking toy bricks, such as Legos.

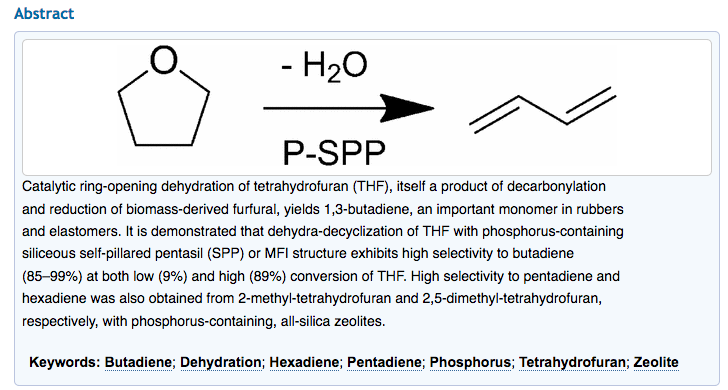

There are three main stages in the new chemical process. It starts from sugars derived from biomass, such as grass. The sugars are converted into other compounds. The breakthrough came in the third stage, using the newly developed “phosphorous all-silica zeolite” catalyst. With it, the team was able to convert a compound called furfural to butadiene with a 95 percent yield.

The University of Delaware’s Catalysis Center for Energy Innovation is funded entirely by the U.S. Department of Energy, and is a partnership designed to transform biomass into fuel and chemicals. The partnership includes the University of Delaware and Brookhaven National Laboratory, the California Institute of Technology, Columbia University, Georgia Institute of Technology, Lehigh University, Rutgers University, the University of Massachusetts, University of Minnesota, and University of Pennsylvania.

Comments

Post a Comment