When it comes to 3D printing, the sky is the limit. As 3D printing technology continues to advance, applications can be as far reaching as airplane and automobile parts to medical devices and even anatomically correct, biocompatible models. Although 3D printing technology is developing at a rapid pace, the technology itself is not new. It emerged in the 1980s as a means of creating rapid prototypes. In recent years the applications for 3D printed models have evolved with the available hardware, software, and printable materials. Evolving technology, paired with the creative and innovative minds of scientists, engineers, and physicians, has been the launching pad for developments within 3D printing technology specific to healthcare. One way 3D printing technology is poised to create better patient outcomes is in creating an anatomically and patient-specific models to aid in surgery and medical procedures. With the capability to 3D ...

From food and children’s toys to electronics and medicine – packaging is a big part of the world we live in. It allows us to rest assured the products we are using are free of bacteria, clean of dust and, to some extent, water. However, some packaging can allow water to slip through, which can damage products. And no one likes a product to be damaged before the package is even opened, especially with how difficult it can be to remove a product’s pesky packaging. However, product packaging may be getting a little boost from our good friend graphene.

Reported in ACS Nano, scientists have developed graphene-infused packaging to help reduce product’s exposure to moisture, extending packaging lifespan for moisture-sensitive products. According to Plastics Today, researchers used chemical vapor deposition to synthesize a single layer of graphene and then transferred the graphene to a polymer film. After doing an accelerating aging test on the product, it was discovered that an organic photovoltaic device wrapped in the graphene film could have a lifesp of over one year. This is compared to a less than 30 minute lifespan for a polymer without the graphene coating. All of this cool science decreases the amount of water that can pass through by a million fold – yes, you read that right!

Packaging needs to restrict moisture exposure from entering at less than 10-6 grams per square meter per day to maximize the lifetime of a moisture-sensitive device, according to Praveen C. Ramamurthy. Today’s packaging is nowhere near reaching that goal, but as scientists continue to make incredible advancements in the world of product packaging, there is not telling what the future holds!

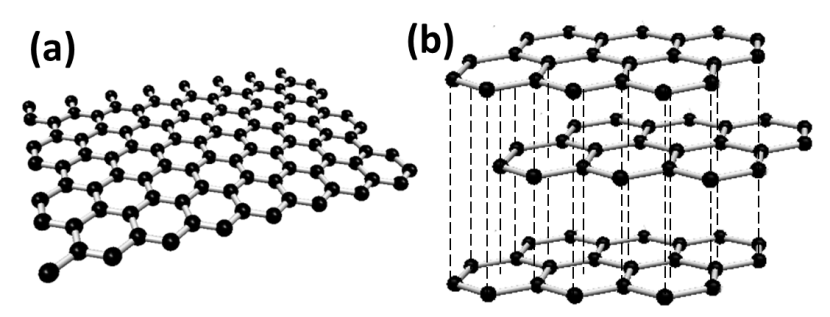

And graphene’s capabilities don’t end there. It has the ability to enhance a variety of other products made from polymers, ceramics and metals. According to a past PSI blog, “Graphene is a sheet of pure carbon, one-atom-thick and arranged in a regular hexagonal pattern. It is extremely light. If it were 1 square meter in size, it would weigh 0.77 milligrams.” However, despite how small graphene is, it possesses strength and withstands heat.

The science industry keeps us on our toes and our curious bunch stays on top of exciting industry advancements – it is so important to our daily lives. It is reassuring to know while we are analyzing in the lab, brilliant researchers are in the process of new and exciting discoveries. Now, if only someone could find a way to help us remove product packaging easier!

Comments

Post a Comment