When it comes to 3D printing, the sky is the limit. As 3D printing technology continues to advance, applications can be as far reaching as airplane and automobile parts to medical devices and even anatomically correct, biocompatible models. Although 3D printing technology is developing at a rapid pace, the technology itself is not new. It emerged in the 1980s as a means of creating rapid prototypes. In recent years the applications for 3D printed models have evolved with the available hardware, software, and printable materials. Evolving technology, paired with the creative and innovative minds of scientists, engineers, and physicians, has been the launching pad for developments within 3D printing technology specific to healthcare. One way 3D printing technology is poised to create better patient outcomes is in creating an anatomically and patient-specific models to aid in surgery and medical procedures. With the capability to 3D ...

Just like there are many ways to “skin a cat,” there are various ways to stitch his wounds as well. The use of polymers in sutures, as with many medical devices, is becoming more varied than ever before.

Reimagining PGLA

The newest way is with the use of nanofiber mats made up of the polymer poly(lactic-co-glycolic-acid) or PGLA. This method has been previously examined for sealing wounds; however, the technique had fallen away because of concerns about depositing the materials safely. The method currently used for creating the mats involves electrospinning, which uses electric currents and can damage tissue when the mats are created in situ.

Spray-On Healing

Researchers at the University of Maryland, College Park, found a way to deposit the nanofiber mats in a precise and efficient manner. The deposition is made by using a standard airbrushing machine that can be purchased at your local hardware store. When the fibers are airbrushed onto the target, they can take the shape of the area and promote healing.

Bioengineer Peter Kofinas explained that this type of material can be used as suture and may also be used for transporting biodegradable, controlled-release drug implantsas well as tissue engineering scaffolds. The material was tested in the lab to seal cuts made to the lung, liver, and intestine. It also proved capable of closing a hernia in the diaphragm. Complete degradation was found to occur after 42 days.

The formulation was tweaked based on the airbrush technique until the researchers were content with their findings. Acetone was used as a solvent to control the thickness of the PGLA fibers. Optimal deposition was found using fibers with a diameter of 370 nm. Before depositing the polymeric mat, the acetone evaporated, leaving no toxic residue to interfere with wound healing.

‘Using an airbrush to deposit biomaterials directly onto tissue is quite enticing and has potential in many areas of medicine,’ says Jeffrey M. Karp, a bioengineer and co-director of the Center for Regenerative Therapeutics at Brigham & Women’s Hospital in Boston.

Traditional Sutures

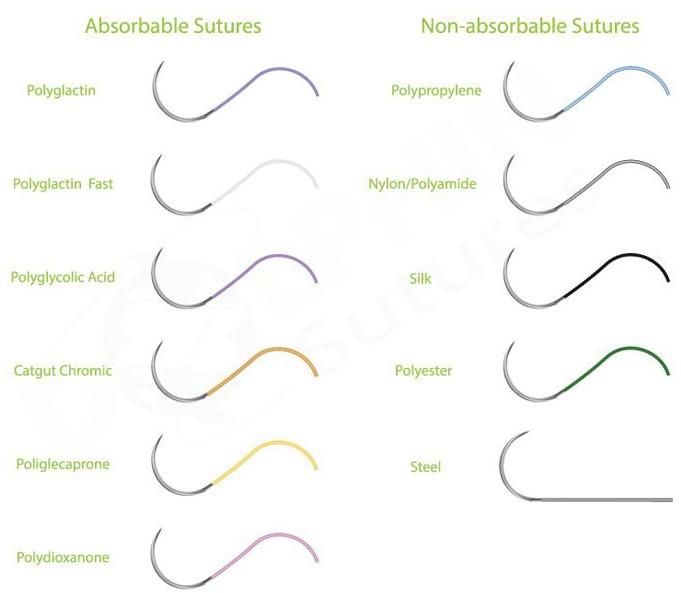

Traditional sutures are made from biological sources like the Chromic suture and from polymers (for example, polyglactin 910). There are several different types of sutures: absorbable, non-absorbable, braided, and non-braided. They come in different-size diameters as well. It’s important to choose the proper suture, as each characteristic is important to the healing process of the particular wound. Absorbable sutures break down in the body. Non-absorbable sutures will be removed. If used inside the body, they will remain in the tissue. Braided tissue is a collection of filament strands woven together. Non-braided tissue consists of a single filament strand.

Absorbable surgical sutures are made from various materials and, depending on the materials, the absorption can take anywhere from 10 days to eight weeks. Synthetic suture materials are made from a variety of polymers, including polyglycolic acid, polylactic acid, and polydioxanone. Monocryl™ is made from poliglecaprone 25 (a copolymer of glycolide and epsilon-caprolactone) and is manufactured by Ethicon®. Catgut suture is the original absorbable suture. It is a sterile monofilament made from the connective tissue of beef or sheep intestines.

Non-absorbable sutures are made from many different materials depending on the application involved. Nylon, polyester, polyvinylidene fluoride (PVDF), polypropylene, and ultra-high molecular weight polyethylene (UHMWPE) are a few of the synthetic non-absorbable sutures. Gore-Tex® suture is also non-absorbable and composed of a proprietary expanded polytetrafluoroethylene (ePTFE). Steel suture is made from 316L stainless steel. Silk is the original non-absorbable suture material derived from an organic protein called fibroin.

Technological advancement has allowed the inclusion of 316L stainless steel staples to close wounds as well as surgical glue (cyanoacrylate). They both are fast and effective methods of suturing.

So the next time you’re in the emergency room and the doctor pulls out an airbrushing machine, don’t assume he’s going to start repainting the place. Just hold out your boo-boo and say “Ahhhhh.”

Comments

Post a Comment