When it comes to 3D printing, the sky is the limit. As 3D printing technology continues to advance, applications can be as far reaching as airplane and automobile parts to medical devices and even anatomically correct, biocompatible models. Although 3D printing technology is developing at a rapid pace, the technology itself is not new. It emerged in the 1980s as a means of creating rapid prototypes. In recent years the applications for 3D printed models have evolved with the available hardware, software, and printable materials. Evolving technology, paired with the creative and innovative minds of scientists, engineers, and physicians, has been the launching pad for developments within 3D printing technology specific to healthcare. One way 3D printing technology is poised to create better patient outcomes is in creating an anatomically and patient-specific models to aid in surgery and medical procedures. With the capability to 3D ...

We might be able to build tougher airplanes, stronger bridges, and harder body armor, thanks to the research conducted by materials engineers at the University of Nebraska-Lincoln. Yuris Dzenis, professor of mechanical and materials engineering, and his team at the university developed an unusually thin polyacrilonitrile nanofiber — a kind of a synthetic polymer similar to acrylic — by using a process called electrospinning, reports Next Big Future.

As the website explains, the researchers found that the process produced a counterintuitive result:

The process involves applying high voltage to a polymer solution until a small jet of liquid ejects, resulting in a continuous length of nanofiber. They discovered that by making the nanofiber thinner than had been done before, it became not only stronger, as was expected, but also tougher.

“Whatever is made of composites can benefit from our nanofibers,” Dzenis says in a news release from the university. “Our discovery adds a new material class to the very select current family of materials with demonstrated simultaneously high strength and toughness.”

The toughness probably comes from the nanofiber’s low crystallinity. The molecules are structurally unorganized so there’s room for them to move around, allowing the material to absorb energy.

Toughness is a measure of how well a material absorbs energy without breaking. A ceramic plate, for example, is strong because it can carry heavy loads, but it isn’t tough because if dropped, it would not absorb the energy of the impact well and shatter. A rubber ball, on the other hand, is not strong because its shape can be easily changed. But it is tough because it won’t easily break.

Similar recent research has shown that electrospun polymer nanofibers can be strengthened even if their diameter is reduced. However, their toughness has not been analyzed.

Dzenis and his team found that a reduction in the fiber’s diameter from 2.8 microns to 100 nanometers resulted in its elasticity from 0.36 to 48 GPa. Its strength increased from 15 to 1,750 MPa, and its toughness increased from 0.25 to 605 MPa. GPa (gigapascal) and MPa (megapascals) are units of measure common in materials science and have largely replaced pounds per square inch (psi). Six hundred MPa is roughly equivalent to 87,000 psi.

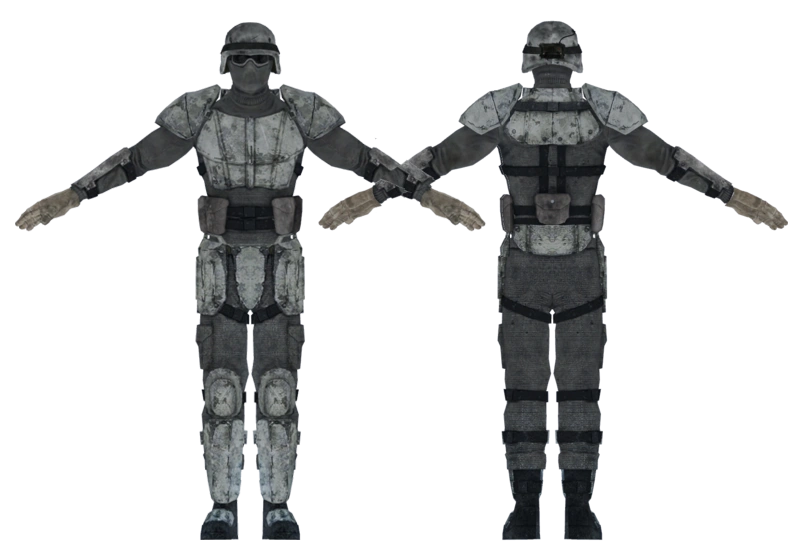

“If structural materials were tougher, one could make products more lightweight and still be very safe,” Dzenis says. He thinks his innovation will improve protective materials, such as body armor. “To stop the bullet, you need the material to be able to absorb energy before failure, and that’s what our nanofibers will do,” he says.

Comments

Post a Comment