When it comes to 3D printing, the sky is the limit. As 3D printing technology continues to advance, applications can be as far reaching as airplane and automobile parts to medical devices and even anatomically correct, biocompatible models. Although 3D printing technology is developing at a rapid pace, the technology itself is not new. It emerged in the 1980s as a means of creating rapid prototypes. In recent years the applications for 3D printed models have evolved with the available hardware, software, and printable materials. Evolving technology, paired with the creative and innovative minds of scientists, engineers, and physicians, has been the launching pad for developments within 3D printing technology specific to healthcare. One way 3D printing technology is poised to create better patient outcomes is in creating an anatomically and patient-specific models to aid in surgery and medical procedures. With the capability to 3D ...

A new formulation of polyurethane rigid foams — commonly used in household appliances — could play a key role in the reduction of environmentally damaging hydrofluorocarbons, also known as HFCs.

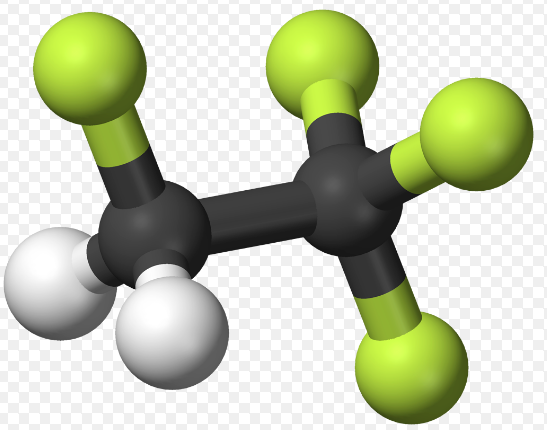

HFCs refer to a class of partly chlorinated and fluorinated hydrocarbons, used as an alternative to chlorofluorocarbons in foam production, refrigeration, and other processes. HFCs do not cause damage at the local level, but their manufacture contributes to greenhouse gas pollution. The compound absorbs infrared radiation, subsequently trapping the energy within the Earth’s atmosphere and aiding in global warming.

Some forms of HFCs don’t readily break down and instead hang around in our atmosphere, continuing the global warming cycle. Additionally, the HFCs can reach the outer atmosphere where it is broken down by solar radiation, but the resulting chemicals are so volatile they can destroy ozone molecules. In 2013, China and the United States both agreed to begin phasing HFCs out of production.

In response to this phase-out, appliance manufacturers have been busy looking for alternatives. One example is consumer refrigerator giant Whirlpool Corporation. Whirlpool just announced a new line of products that use a BASF-developed formulation polyurethane rigid foam called Elastocool®. The foam is applied using Honeywell’s Liquid Blowing Agent (LBA) called Solstice®. This is the first polyurethane insulation system on the commercial market that utilizes hydrofluoroolefin (HFO) foam blowing agent that has an ultra-low global warming potential (GWP).

This is the first time a new system has been used to replace the traditionally used HFC-based foam that has a GWP of 700-1000. By comparison, the Solstice LBA produces a GWP of 1. The new insulation system provides several significant benefits, including increased shelf-life stability. Better insulation properties allow 2-3 percent improvement in energy efficiency. The application process distributes the foam in a more uniform manner, delivering a more consistent energy-efficient product. The time it takes to fabricate the product is cut due to a decrease in de-mold time (the recommended time that a cured part can be removed from a mold), thereby increasing factory output.

‘As a key development partner to Whirlpool, we’re excited to help bring this premiere commercial polyurethane insulation system to market,’ remarked Jozef Venner, Business Director, Performance Materials Consumer Group at BASF. ‘Moving forward, we’re working on additional improved formulations to continue to be on the forefront of energy-efficient systems that provide best-in-class thermal performance for our customers.’

Polyurethane foams are typically made in large blocks by either a continuous extrusion process or a batch process. The blocks can be cut into sheets or even molded to into shapes for parts. The foam is available in different densities ranging from 2 pounds per cubic foot to 50. The cost increases with density. Foams at the same density can have significant differences in strength due to the fabrication process as well as the curing temperature used in the process. The foams can be closed cell, where the bubbles from production are intact, or open cell, where the bubbles are broken but the material is stiff enough to retain the shape. The closed-cell rigid foam is used as a thermal insulator because of its low thermal conductivity.

Polyurethane rigid foams are widely known for offering unsurpassed insulation for household refrigerators. They are also used in many other household appliances and products such as freezers, picnic coolers, thermo wares and water coolers. The foam is cost-efficient and provides a superior bond between the interior and exterior shells. The bond provides a gap-free insulating layer formed by the rigid foam that remains unchanged by the vibration of the refrigerator. Due to the durability of polyurethane foam, the energy efficiency of the refrigerator should last for the lifetime of the product.

The Elastocool® rigid foam material made by BASF is a fine, closed-cell structure with specifically constructed chemistry. The result is a product with exceptional mechanical and physical attributes, and with the Solstice® Liquid Blowing Agent (LBA) it’s environmentally friendly, too. The foam can be customized based on the manufacturer’s processing needs such as fill, curing rates, and viscosity. The flexibility of the foam fabrication can stand up to the demand of today’s high energy-efficiency requirements and well into the future.

Other appliance companies have begun to move away from HFCs as well. In 2011, GE switched from using HFCs in one of its plants to using cyclopentane as the insulation foam blowing agent in their top-freezer refrigerators. Moreover, in 2012 GE began using cyclopentane on its French-door refrigerators with a bottom mount. In testing its refrigerators blown with cyclopentane, GE found that the insulating foam had an increased efficiency and these products exceeded U.S. Energy Star standards. Honeywell claims in its studies that the LBA outperformed the cyclopentane in energy efficiency.

Regardless of which polymer product is better, when HFCs are reduced in the environment, everybody wins.

Comments

Post a Comment