When it comes to 3D printing, the sky is the limit. As 3D printing technology continues to advance, applications can be as far reaching as airplane and automobile parts to medical devices and even anatomically correct, biocompatible models. Although 3D printing technology is developing at a rapid pace, the technology itself is not new. It emerged in the 1980s as a means of creating rapid prototypes. In recent years the applications for 3D printed models have evolved with the available hardware, software, and printable materials. Evolving technology, paired with the creative and innovative minds of scientists, engineers, and physicians, has been the launching pad for developments within 3D printing technology specific to healthcare. One way 3D printing technology is poised to create better patient outcomes is in creating an anatomically and patient-specific models to aid in surgery and medical procedures. With the capability to 3D ...

From polyethylene cling wrap and plastic buckets to loudspeakers, lab equipment and long underwear made from polypropylene, some of the world’s most useful polymers start life as olefins. Olefins are created when one or more pairs of hydrogen and carbon atoms link together by a double bond. Polymerization of the olefins creates — surprise! — polyolefins, the class of polymer that is the most-produced, most-used type of plastic in the world. Polyethylene and polypropylene are two examples of widely used polyolefins.

Their crystalline structure makes polyolefins tough. What’s more, they have a high resistance to heat and chemical corrosion. As amazingly useful as they are, however, there’s a problem with polyolefins: they’re hard to analyze.

The properties that make polyolefins so very useful also contribute to the difficulty in analyzing their molecular weights and molecular weight distributions. Analysis of polyolefins often requires researchers to use very high temperatures and strong solvents such as trichlorobenzene in order to dissolve the polymers into a testable form.

The high temperature and handling requirements of polyolefin analysis means dissecting what a given polyolefin is all about can be a tremendous challenge. It takes a high level of expertise to do the job right. Even when they successfully dissolve a polyolefin, scientists may find their sample re-crystalizes before they can complete their analysis.

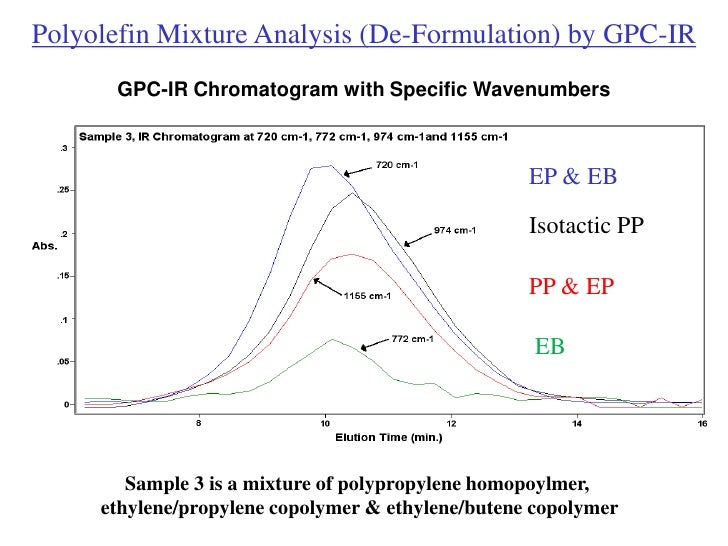

Gel permeation chromatography (GPC) is a standard analytical tool for measuring molecular weights of polymers. GPC allows scientists to characterize the molecular weight distribution of a sample — a critical property that speaks directly to the physical properties, durability and real-world behavior of polymers. Knowing a polymer’s molecular weight can be useful in raw material selection, and in understanding how manufacturing processes such as molding and drying might affect the molecular weight of a material.

However, GPC testing requires the use of solvents to reduce a sample into a testable form. Most GPC instruments operate best at lower temperatures, and aren’t efficient at managing the high temperatures needed to facilitate the analysis of polyolefins. The need for intense heat and the presence of a highly corrosive chemical can make it very difficult to preserve the integrity of samples.

High-temperature GPC systems are the solution for successfully analyzing polyolefins. Systems like the Tosoh EcoSec High Temperature GPC System (Polymer Solutions Incorporated recently purchased one) allow scientists to conduct GPC analysis of polyolefins while maintaining sample integrity and a constant, high temperature. High-temperature GPC analysis allows us to analyze the molecular weight of some of the polymers most commonly used by our clients across a variety of industries.

Comments

Post a Comment